5 truths regarding decorative landscape stone that you should know

1. Size

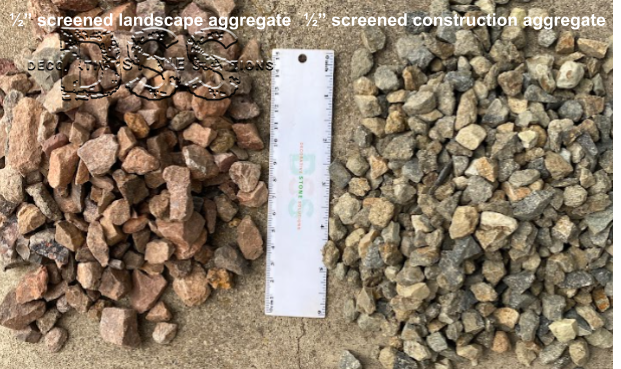

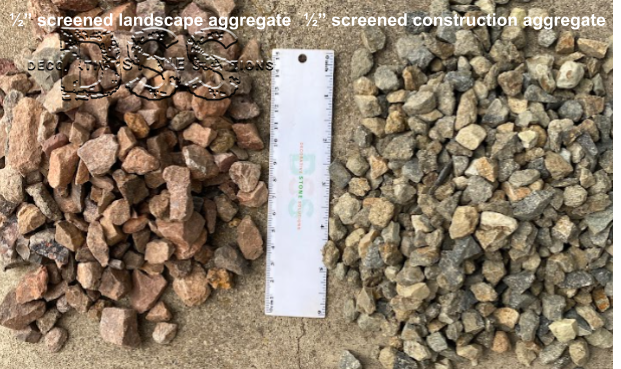

- The same screen size can vary from quarry to quarry (one quarry’s ¾” is not screened to the the same size as another's ¾”). While there are standards in the screen sizing of construction grade aggregates, the same can not be said for quarries producing decorative only stones. Decorative landscape stone is typically judged by its color and aesthetics, and not by its performance properties such as hardness or size.

2. Texture

a. Crushed/angular rock is more readily available than round rock

b. Crushed comes from mostly from hard rock quarries that are in the business of producing smaller rock out of blasted large rock

c. Have the ability to crush and screen to just about any size the project calls for

d. Round rock are naturally occurring products from current or ancient riverbeds and oceans. This makes them more of a limited resource than crushed angular stone, especially here in California.

e. Only available in the size options that nature provides.

f. Many sources are limited to 8” or less in size

3. Color

a. Changes over time

- As a quarry digs and blasts its way deeper into the earth or farther away from the original vein, the color of the deposit/formation can change.

- There is no guarantee that the color coming out of the ground today will match the color from last month, much less years or decades ago.

- Stone that has been unearthed, installed, and exposed to natural weathering processes for years often oxidizes and darkens over time making the newly quarried materials appear lighter in color.

4. Decreasing number of local quarries is creating a shortage of local aggregates

A. As existing quarry locations start to reach their reserve limits, new quarries must be established. This is especially true in high growth areas. Mining is often seen as a controversial land use during the permitting process. So it can be very difficult to get permitting for new aggregate quarries.

B. Land-use planners and decision makers in California are faced with balancing a wide variety of needs in planning for a sustainable future. Universal need, increasing demand, the economic and environmental costs of transportation, and multiple land-use pressures all compound to make the actions of land-use planners and decision makers charged with planning for a sustainable future that much more important.

C. As an example of a pending shortage, California currently only has permitted resources to meet approximately one-third of aggregate demand over the next 50 years.

D. Aggregate is an absolute essential for commodities such as Portland Cement Concrete, asphaltic concrete, plaster and stucco. They are also necessary for projects needing railway ballast, erosion control, and pipe fill. Because aggregates are used in so many products and applications, a shortage will affect a community’s ability to provide for new construction projects and infrastructure.

E. The location of aggregate resources too close to urban or environmentally sensitive areas can limit or prevent their development. Resources may also be located too far from a potential market to be economic.

F. This issue is made worse when NIMBYism comes into the picture. These people that don’t want a quarry near their community need to be educated about the detrimental effects (environmental and economic) of having to ship aggregates long distances.

- Increased costs of all construction projects

- Increased Carbon Footprint

- Higher traffic congestion

- Increased air pollution

5. One Man’s trash is another man’s treasure.

A. Most quarries produce rock for construction & civil projects such as concrete and asphalt aggregates, trench backfill, jetty and erosion control projects, road base, etc.

B. The byproduct of this is that most aggregate producers are regional. If the main purpose is construction grade product then the least expensive rock is going to be used on a project, which typically means it will be sourced from the quarry closest to the delivery site. Due to ever increasing freight costs, it isn’t economically feasible to ship construction grade products long distances where the trucking costs are going to exceed the material costs

C. In California, quarries producing stone and aggregates for use in the decorative landscape industry make up a very small percentage of aggregates being produced. The demand is just not high enough to support an operation devoted solely to the landscape industry. Because of this, most decorative landscape rock comes from the construction aggregate focused quarries mentioned above.

D. Stone used in the decorative landscape industry is often the exception to the rule of a material needing to come from a regional quarry. Most regions have geologic deposits that are mostly in the same color range. In Southern California the predominant colors are shades of grays and golds. In order to get something other than that, material must be trucked in from other regions or states such as Arizona and Nevada where reds, pinks, and even purples are typical. Construction and Engineering projects generally don’t care what color the rock is as long as it meets the performance standards required.

The same is not true for rock being used in a decorative landscape project. If an owner or designer wants to differentiate their project with something other than what is locally available and typical, they have to broaden their search to include materials from outside their region. This choice comes with the understanding that the landed cost of a non-regional material will be significantly greater due to higher shipping costs and resources used.

In fact, oftentimes the shipping cost will exceed the material costs. Most crushed rock is roughly the same price, what separates an expensive rock from an inexpensive one is how many times it is handled and how many miles it has to travel to the final destination. As I am often heard saying “Rock is cheap, moving it around is expensive”.

Category : News