Learn The 3 Ways Landscape Rock Is Sorted

Decorative landscape rock is generally sorted/screened to size by 3 methods.

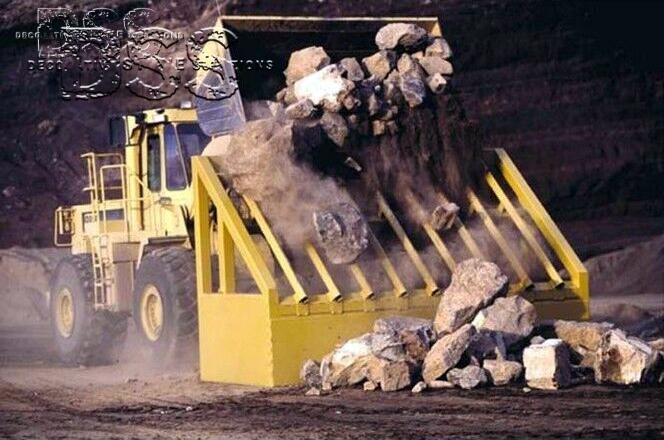

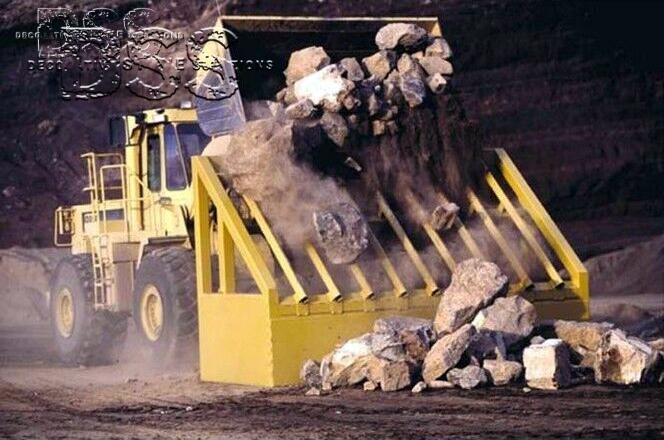

1) Static “Grizzly” Screen

Static screens are commonly referred to as Grizzlies and are the most basic and simple of all screens used to sort rock sizes. This type of screen is often used to prescreen out the larger rock before sending material into a crusher or screening plant (which could be damaged by large pieces).

Grizzlies are made of parallel bars running at an angle from front to back. The bars are set at an equal distance apart. This allows material smaller than the set distance to fall through to the belly of the screen and larger material to slide off the front.

Material is dumped onto the backside of the grizzly with a loader. This is a fairly slow method, as nothing is being processed until a new load of material is dumped onto the screen. It also requires constant removal of both the oversize and undersized material to make room for the next load to be processed.

The advantages of this screen are a construction of extremely heavy duty steel and no moving parts. It is able to process very large rock without damaging the screen: up to ¼ ton rip rap.

The drawback to this method of screening is that it doesn’t produce very well sized material. Since material is only being separated by a single dimension (bars on only 2 sides of rock), there is a higher possibility of getting material that is larger or smaller than desired. [Compared to the other sorting methods described here]

We’ve heard it described as the “phonebook” phenomena. If a phone book were to fall on a grizzly screen in the upright vertical position it would pass through the screen. If the same phonebook were to fall on the screen in a horizontal position, it would be wider than the distance between the bars and slide off onto the oversize pile. This helps explain why there is typically a percentage of oversized material in any product that has to be screened by a grizzly. If bars are set to an 8” distance for a 4”-8” rock, the reality is that some pieces larger than 8” are going to pass through because they fell on the screen with one of their dimensions that is less than 8”.

2) Vibrating Deck Screen Mesh

This type of screen is placed at an angle and mechanically shaken/vibrated so that material moves across it. It looks like an extremely heavy duty version of a typical window screen, with square openings. This process provides a truer size than the static screening method, as there is a four sided hole that the material must fall through. This type of screen is typically limited to only handling smaller material (4”-6”maximum). Larger rock material is very hard on the screen’s metal mechanical parts, and will cause premature wear and expensive repairs.

The advantage of this method is material can be measured based on the size of the screen openings. As the material dances across the screen, particles that are smaller than the openings fall through. Particles that are larger stay on top and eventually exit the end of the screen into a pile.

The material that stayed on top of the screen now has a minimum dimension of what the width of the screen opening is. For example: If the screen openings measured 2” across, the sorted material that did not pass through the screen will be 2” and larger.

Most decorative stone screening plants will have several decks or “layers” of screens, one over another. The screen with the largest openings will be on the top level, followed by a smaller sized screen on the 2nd level, then even smaller screens on the following levels. Material smaller than the last screen would typically be considered fines.

Each deck has a conveyor belt leading from the screen which transports the sorted material to a stock pile.

There will be some plus and minus on material sizing with this method, since it is possible for pieces to pass through that have a larger dimension than the screen opening. If the material has a dimension on a different side that is smaller than the screen opening, it may fall onto the screen with this smaller dimension and pass through.

For example: Think of a long slender piece that while the length is much larger than the opening, its width is smaller than the opening. If it falls on the screen with the width-wise instead of length-wise, it will pass through to the next deck below.

3) Hand Sorted and Palletized

As it sounds: Material is sorted by hand for color, shape and size. This is obviously the most labor intensive and expensive way to sort rock, but it yields the most consistent and cleanest product with very little waste.

Material is typically eyeballed for size. A tape measure is not used to verify the sizing of each piece selected, and can occasionally create issues when there are multiple laborers sorting the same product. What one person considers a 6”-10” may not be the same as the person next to them. Slight size variation can be expected from pallet to pallet.

Decorative Stone Solutions strives to provide you with the highest quality landscape stone. We know the importance of your project looking its absolute best. Thank you for trusting us with your landscape stone needs. For questions on which product to use for your project, please give call us at 800-699-1878. You can also check our Design Gallery for ideas or our Product Guide for options.